Composites are made up of two different materials exhibiting different properties. In fact, the new material counteracts each of the earlier materials’ weaknesses and hence, is more useful than the individual components.

The high performance composites value chain comprises raw material suppliers, manufacturers, distribution channels, and the end-users. The major materials used in the manufacturing of these composites are carbon fiber, boron, epoxy resin, and phenol. Epoxy resin and phenol are used to manufacture the matrix, while carbon, glass, and aramid are used for making fibers. These materials render strength to the composites and also reduce their weight.

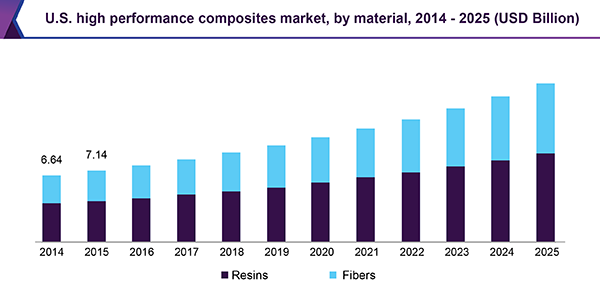

Increasing penetration of high performance composites in aerospace and automotive industries is expected to be the major driver of the market over the forecast period. The global number of new car sales increased from 85.6 million in 2013 to 93.9 million units in 2016. This represents a CAGR of 3.1% during this period. New cars, in order to abide by new compliances and regulations regarding fuel consumption, have started using carbon composites in extensive amounts. These composites are lighter in weight as compared to aluminum and steel and hence, reduce the kerb weights of vehicles.

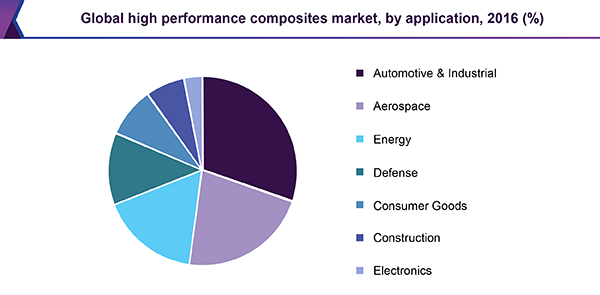

Asia Pacific witnessed the highest demand for high performance composites in 2016 owing to growing construction and defense sectors. This region is driven by growing demand for lightweight materials from emerging countries including China and India. Besides, developed countries such as Japan and South Korea have also witnessed considerable growth on account of increasing demand from electronics and automobile sectors.

One of the major advantages of high performance composites is its lower mass content as compared to steel and iron. Due to this, less amount of materials such as fasteners and joints are required to hold the product together. This not only decreases the kerb weight of the product, but also increases its stiffness, making it stronger.

The industry is characterized by the presence of a limited number of manufacturers scattered globally. However, these players have a strong technical knowledge and dense distribution networks. Solvay, Hexcel Corporation, Koninklijke TenCate NV, SGL Carbon SE, and Owens Corning Corporation were some of the major players competing with BASF, which dominated the market in 2016. Expansions into new regions and extensive R&D were some of the commonly adopted strategies by these players in the last six years.

In-depth report on global high performance composites market by Grand View Research: