PMMA is commonly known as acrylic and sold under various brand names such as Plexiglas, Lucite and Perspex. Polymerization of methyl methacrylate (MMA) monomer leads to the formation of this material. The most common method of production is mass polymerization, wherein extruded sheets are often manufactured from polymerized pellets.

The original discovery of this process was made by German chemists Fittig and Paul in 1877. However, it was not until 1936 that the process was further refined to produce acrylic safety glass for commercial applications.

Innovations such as anti-algae coatings, non-yellowing sheets that offer high protection against UV and rain, and unusual design flexibility offered for construction applications have also contributed to industry growth in recent years.

Among all the thermoplastics, this particular plastic possesses the highest surface hardness and is different from conventional plastics owing to its unique properties such as high transparency, UV resistance, high durability and recyclability.

PMMA is completely recyclable as it can be broken down into its constituent parts by using the special thermal process. The product is heated to around 400 degrees Celsius to obtain the staring material methyl methacrylate (MMA). On distillation of the liquid MMA to over 99% purity we get the original material back which can be used again as a starting material.

The material is commonly utilized in aircraft windshields, automotive tail-light covers, signs & displays, lighting fixtures and even aquariums. The material is also widely used in patio roofs and conservatories owing to its ability to withstand extreme weather conditions such as heavy rainfall and snowfall.

The most commonly used product is a soft acrylic film, which is primarily used as a surface laminate material for PVC wallpapers, steel boards and polycarbonate boards. The product also repeatedly contributes to new developments in medical technology. Technological & product innovations such as the introduction of a new PMMA-based microbe resistant compound, Cyrolite Protect 2, has fostered a variety of applications such as disposable medical instruments or infusion accessories in the European market. Other countries such as India, China, Thailand and Malaysia are expected to follow suit, leading to high market growth in Asia Pacific.

Benefits offered by PMMA sheets & films

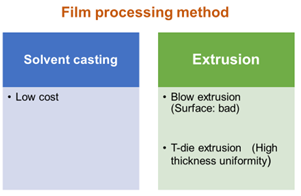

Film processing methods

There are two kinds of film processing methods: solvent casting method and the extrusion method which is further divided into two categories: a T-die extrusion method and a tubular film method. The T-die method involves the process of solidification (a film surface is altered from molten to solid state with the help of a cooling roller). This process is more popular as it results in superior surface smoothness and thickness controllability.

In-depth report on U.S. polymethyl methacrylate (PMMA) film and sheet market by Grand View Research: