Industry Insights

Industrial lubricants, in general, are the fluids that are used to reduce friction between adjacent materials or components. They can be either petroleum-based or water-based and are indispensable to the proper functioning of machinery. They facilitate the reduction of wear and tear between different moving parts. These are increasingly being preferred since they significantly reduce the downtime of operations, thereby improving the overall productivity of the machine.

To view summary of U.S. Industrial Lubricants Market Report, click the link below:

Bio-based lubricants have been gaining importance owing to their environmentally friendly properties. Growing emphasis on aquatic pollution through the unregulated disposal of conventional counterparts has also been a major factor for the development of bio-based alternatives. Rising popularity of these sustainable products is expected to negatively influence the industry growth over the forecast period.

Rapidly increasing demand from the food sector has led to a robust expansion of synthetic food grade oil. The U.S. is a major market in promoting biofuels as an alternative to conventional fuels, on account of stringent government regulations concerning the use of safe food grade oil. The U.S. represents a major food processing market across North America, Europe, and Asia Pacific. It accounts for more than 10% of overall food manufacturing shipments.

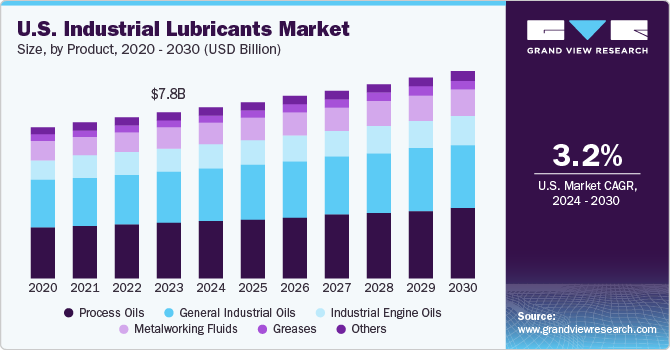

Product Insights

General industrial oils are widely employed to prevent industrial machinery from rust, wear & tear, and other chemical corrosion. They are well-suited for applications that require extreme pressure performance and in all other applications that demand optimum performance. To name a few, they are used in rock drill, sawmill, anti-oxidant, slide way protection carrying machine tools in severe environments, needle/spindle bearing, and heavy-duty bearing applications.

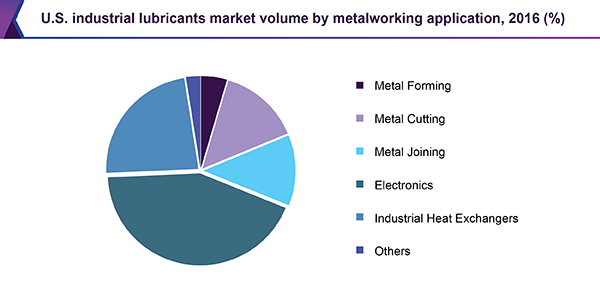

Metalworking fluids are anticipated to witness fastest growth rate by 2025. Metalworking fluids offer superior viscosity to temperature behavior and are therefore stable at extreme temperatures. Moreover, metalworking fluids also have good chemical resistance.

Application Insights

Lubricants used in the chemical manufacturing application results in the lengthening of lubricant and equipment lifespan, reduced oil temperatures, increased production output, reduced friction, heat, wear, energy consumption and extended oil drain intervals.

Textiles industry is anticipated to be the dominant consumer by 2025. High-performance lubricants have historically played a significant role in the operating of textile machinery equipment. These are developed to cope up with the weaving and other types of constraints such as yarn breakage risks, high speed, and yarn abrasion while at the same time anticipating high wash-ability for all finishing processes such as dyeing and coating where auxiliary removal plays a key role.

Energy segment is also projected to generate significant demand over the forecast period. U.S. industrial lubricants for power plants are engineered to perform even in the extreme conditions, such as high temperature as well as wet and dusty conditions. They help in the advancement of the power plant productivity while reducing the operational cost by lowering down friction.

Download U.S. Industrial Lubricants Market report, click the link below:

Report Scope

| Attribute | Details |

| Base year for estimation | 2016 |

| Actual estimates/Historical data | 2014 - 2016 |

| Forecast period | 2017 - 2025 |

| Market representation | Volume in Kilo Tons, revenue in USD Million and CAGR from 2017 to 2025 |

| Regional scope | U.S. |

| Report coverage | Revenue forecast, company share, competitive landscape, growth factors and trends |

| 15% free customization scope (equivalent to 5 analyst working days) | If you need specific market information, which is not currently within the scope of the report, we will provide it to you as a part of customization |